18 min read

Choosing the right hardware materials can make all the difference in how long your project lasts. You don’t want to waste time and money on parts that wear out quickly or break under pressure.

Imagine using materials that stay strong, resist damage, and keep your work looking great for years. You’ll discover simple tips to help you pick long-lasting hardware materials that match your needs perfectly. Keep reading to make sure your next project stands the test of time.

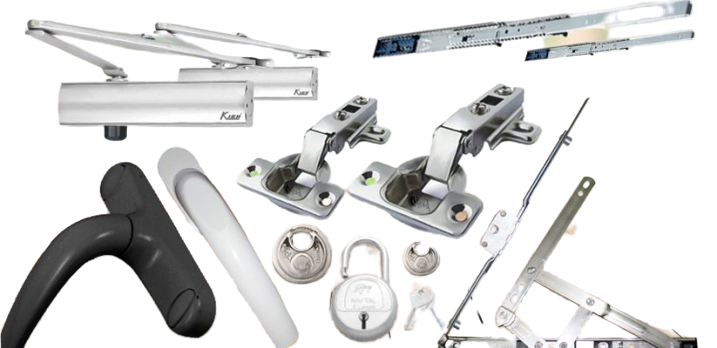

Credit: mccoymart.com

Key Factors In Hardware Durability

Choosing the right materials is important for hardware that lasts a long time. Durable hardware saves money and reduces repairs.

Several factors affect how long hardware materials will perform well. These include strength, resistance to damage, and impact on the environment.

Material Strength And Hardness

Strong and hard materials can handle heavy loads and resist dents. They keep their shape under pressure.

Choosing materials with good strength helps hardware last through daily use and rough conditions.

- Steel is strong and hard

- Aluminum is light but less hard

- Brass offers moderate strength and hardness

Corrosion Resistance

Corrosion causes metal to weaken and fail. Materials that resist rust last longer outdoors and in wet areas.

Look for materials that do not easily react with water or chemicals to avoid corrosion problems.

- Stainless steel resists rust well

- Coated metals have added protection

- Plastic parts do not corrode

Wear And Tear Performance

Hardware faces friction and repeated use. Durable materials resist scratches, dents, and surface damage.

Materials that handle wear and tear keep hardware looking and working well for longer periods.

- Hardened steel resists scratches

- Plastic parts may wear faster

- Surface treatments improve wear resistance

Environmental Impact

Choose materials that cause less harm to the environment. Sustainable options reduce waste and pollution.

Recyclable and eco-friendly materials help protect natural resources and lower carbon footprints.

- Steel and aluminum are recyclable

- Plastic recycling depends on type

- Natural materials can be biodegradable

Common Durable Hardware Materials

Choosing the right material for hardware is important for long-lasting use. Durable materials resist wear and damage.

Strong materials save money by reducing repairs and replacements over time.

Stainless Steel

Stainless steel is a popular metal for hardware because it does not rust easily. It stays shiny and strong even in wet places.

This metal is used for tools, kitchen hardware, and outdoor fixtures. It is easy to clean and very tough.

Titanium

Titanium is a very strong and light metal. It resists rust and corrosion better than many other metals.

This metal is often used in high-quality hardware that must last a long time under harsh conditions.

Brass And Bronze

Brass and bronze are alloys made from copper. They are strong and resist corrosion well.

These metals have a warm color and are often used in decorative hardware and fixtures that need to last.

High-grade Plastics

High-grade plastics are tough and resist many chemicals. They do not rust or corrode like metals.

These plastics are lightweight and used in hardware parts that need to be strong but not heavy.

Material Selection For Different Applications

Choosing the right hardware material is important for long-lasting use. Different uses need different materials to work well.

This guide helps you pick materials for outdoor use, heavy loads, heat, and chemical exposure.

Outdoor Use

Materials used outside must resist weather and moisture. They should not rust or break easily.

Common choices include stainless steel and treated aluminum. These last longer in rain and sun.

- Stainless steel resists rust and corrosion

- Aluminum is light and weather-resistant

- Galvanized steel has a protective zinc coating

Heavy Load Bearing

Materials for heavy loads must be strong and tough. They should hold weight without bending or breaking.

Steel and cast iron are good for these needs. They have high strength and last under pressure.

- Steel offers high tensile strength

- Cast iron handles compressive forces well

- Alloy metals increase strength and durability

High Temperature Environments

Materials in hot places must resist heat and not melt or warp. They keep their shape under high heat.

Ceramics, stainless steel, and some alloys are good here. They stay strong and safe at high temperatures.

- Ceramics handle very high heat well

- Stainless steel resists heat and oxidation

- Nickel alloys have excellent heat resistance

Chemical Exposure

Materials exposed to chemicals must resist corrosion and damage. They should not react or weaken easily.

Plastic, stainless steel, and certain alloys work well. These materials last long in harsh chemical environments.

- Plastic resists many acids and bases

- Stainless steel tolerates many chemicals

- Titanium alloys resist corrosion strongly

Credit: www.topfirefighting.com

Testing And Certification Standards

Selecting long-lasting hardware materials needs careful testing. Testing helps check strength and durability.

Certification standards show that materials meet quality and safety rules. These standards help buyers trust the product.

Mechanical Testing Methods

Mechanical tests measure how strong and tough materials are. These tests check if parts can handle stress and weight.

Common tests include tension, compression, and impact tests. They show how materials behave under different forces.

- Tensile test measures how much force a material can take before breaking.

- Compression test checks how materials react to squeezing forces.

- Impact test shows resistance to sudden shocks or hits.

- Fatigue test checks durability under repeated loading.

Corrosion Testing

Corrosion tests check how well materials resist rust and decay. This is important for metal hardware.

Tests expose materials to moisture, salt spray, or chemicals. This shows how long they last in tough environments.

- Salt spray test simulates exposure to salty, wet air.

- Humidity test measures resistance to damp conditions.

- Chemical resistance test checks materials against acids or bases.

Industry Certifications

Certifications prove that hardware materials meet industry rules. These help buyers and sellers trust the product.

Common certifications focus on safety, quality, and environmental impact. They come from official organizations.

- ISO 9001: Quality management systems for consistent products.

- ASTM standards: Testing and material specifications.

- RoHS: Limits harmful substances in materials.

- CE marking: Shows compliance with European safety rules.

Quality Assurance Practices

Quality assurance ensures materials and products meet set standards. It involves checks during and after production.

Practices include inspections, testing, and process controls. They help catch defects early and keep quality high.

- Incoming material inspection to verify raw materials.

- In-process checks during manufacturing stages.

- Final product testing before delivery.

- Documentation and traceability for quality tracking.

Maintenance Tips To Extend Hardware Life

Choosing long-lasting hardware materials is only the first step. Proper care can help your hardware last even longer. Simple maintenance tasks keep your tools working well.

Regular care prevents damage and saves money. Learn easy ways to maintain your hardware for the best results.

Regular Inspection

Check your hardware often to find problems early. Look for rust, cracks, or loose parts. Early fixes stop bigger damage.

Set a schedule to inspect your hardware weekly or monthly. Use a checklist to track what you checked and found.

- Look for signs of wear and tear

- Check screws and bolts for tightness

- Notice any unusual noises or movements

- Report or fix problems quickly

Proper Cleaning Techniques

Keep hardware clean to stop dirt and dust from causing damage. Use soft cloths and mild cleaners. Avoid harsh chemicals that can harm the material.

Dry the hardware after cleaning to prevent rust. Clean tools after each use to keep them ready and safe.

- Use a brush for hard-to-reach areas

- Wipe metal parts with oil to protect them

- Remove grease and grime regularly

- Never soak hardware in water

Lubrication Guidelines

Lubricate moving parts to reduce friction and wear. Use the right type of oil or grease for each hardware piece. Too much lubricant can attract dirt.

Apply lubrication after cleaning and before storage. Check manufacturer instructions for the best lubricant type.

- Use light oil for small hinges and locks

- Choose grease for heavy machinery parts

- Apply lubricant sparingly

- Wipe off excess lubricant to avoid buildup

Storage Recommendations

Store hardware in dry, cool places to prevent rust and damage. Avoid damp or hot areas. Proper storage keeps hardware safe and ready.

Use racks or boxes to keep hardware organized. Label storage containers to find items easily. Keep heavy tools off the floor to avoid moisture contact.

- Keep hardware away from direct sunlight

- Use silica gel packs to control moisture

- Store tools in closed cabinets or boxes

- Arrange items to prevent damage from falling

Credit: yafa.co.in

Emerging Trends In Hardware Materials

Choosing the right hardware materials is key to making products that last. New materials help improve strength and durability.

These trends show how technology and design shape better hardware for the future.

Advanced Alloys

Advanced alloys mix metals to create stronger, lighter materials. They resist corrosion and wear better than old metals.

These alloys help hardware last longer in tough conditions. They are common in tools and machinery parts.

Composite Materials

Composite materials combine two or more substances to make stronger products. They can be lighter than metal but very tough.

Composites are used in hardware parts that need to be both strong and light. They also resist rust and damage.

Nanotechnology Applications

Nanotechnology changes materials at a tiny scale. This can make surfaces harder and more resistant to scratches.

It helps create coatings that protect hardware from water, dirt, and wear. This keeps tools working longer.

Sustainable Material Choices

Sustainable materials come from sources that do not harm the environment. They reduce waste and save resources.

Using recycled metals and biodegradable parts helps make hardware eco-friendly. These choices support a cleaner planet.

Frequently Asked Questions

What Are The Best Materials For Long-lasting Hardware?

Stainless steel, brass, and titanium are top choices for durable hardware. They resist corrosion, wear, and extreme conditions, ensuring longevity and reliability in various applications.

How Does Material Choice Affect Hardware Durability?

Material determines resistance to rust, wear, and mechanical stress. Choosing high-quality metals or composites enhances hardware lifespan and performance under daily use and harsh environments.

Are Stainless Steel Hardware Materials Better Than Others?

Yes, stainless steel offers excellent corrosion resistance, strength, and low maintenance. It’s ideal for indoor and outdoor hardware requiring durability and long-term reliability.

What Role Does Corrosion Resistance Play In Hardware Selection?

Corrosion resistance prevents material degradation from moisture and chemicals. Selecting corrosion-resistant materials prolongs hardware life and maintains appearance and function over time.

Conclusion

Choosing durable hardware materials ensures longevity and reliability. Quality materials resist wear and tear. They save money over time. Strong materials need less replacement. This reduces maintenance hassle. Investing wisely in materials pays off in the long run. Consider material compatibility for specific needs.

Evaluate options based on environment and usage. Make informed decisions for better outcomes. Research thoroughly before purchasing. Durable materials ensure safety and efficiency. Prioritize quality over cost for lasting benefits. Remember, the right choice supports sustained performance.